Table of Contents

Introduction

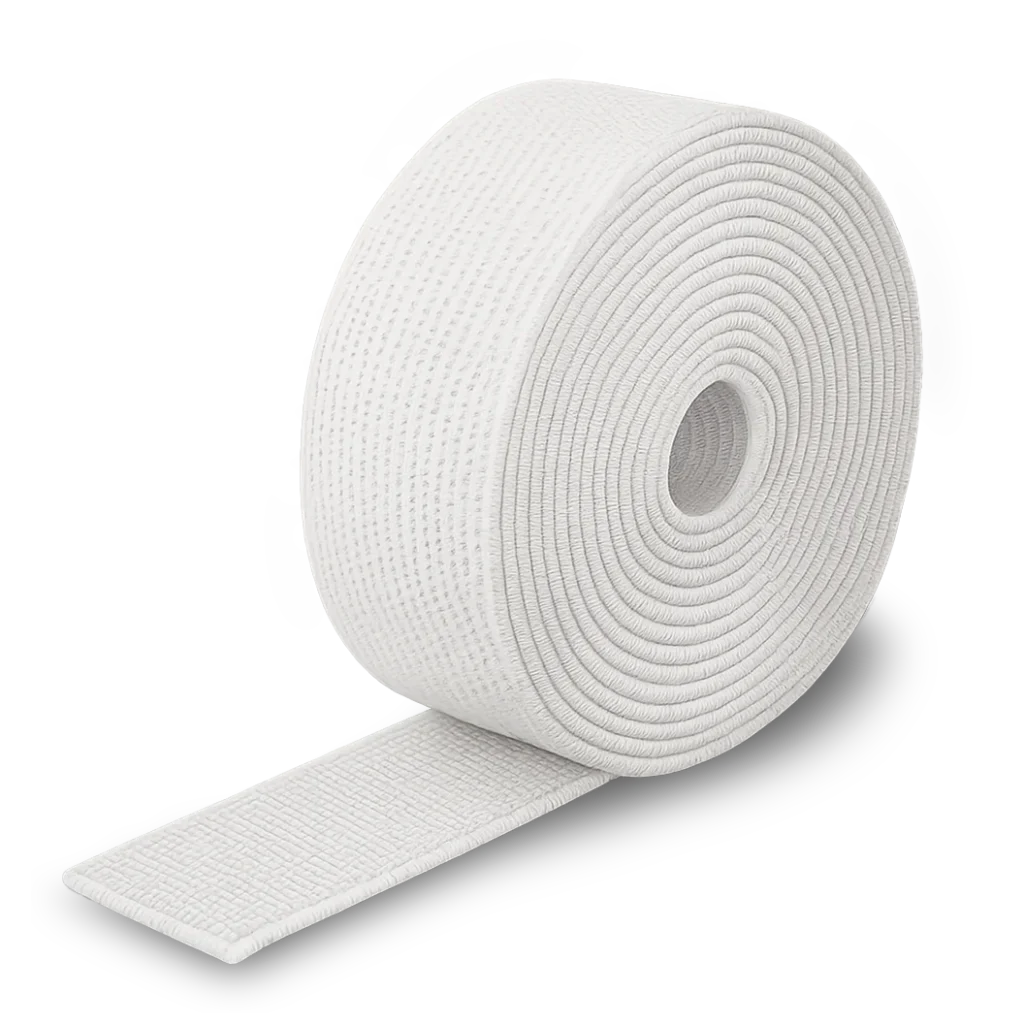

In the garment and textile industry, elastic tape manufacturers might seem like a tiny detail, but they play a big role in how a garment feels and performs. Whether it’s innerwear, sportswear, kidswear, shapewear, or even medical garments, elastic tapes affect comfort, fit, and durability every single day. A wrong elastic choice can spoil the fit of a well-designed garment, while a good-quality elastic goes unnoticed but makes the wearer feel the difference.

Even with such importance, many buyers and brands don’t really know what happens before elastic tapes reach their factory. There is a complete process going on in the background, starting with understanding the buyer’s requirements, moving through sampling and testing, and finally reaching bulk production and dispatch. This blog breaks down that entire journey in a simple and practical way, helping buyers make better decisions when working with us.

Understanding the Role of Elastic Tape Manufacturers

Elastic tapes used in garments are usually not ready-made or one-size-fits-all products. Each type of garment has its own needs. Innerwear requires softness and comfort, waistbands need strong recovery, and industrial or medical garments demand durability and performance. This is where tape manufacturers add real value, going much beyond simple production.

Their job is not just to supply rolls of elastic. They translate the buyer’s requirements into precise technical standards and ensure their adherence throughout the bulk production process. This involves a solid understanding of yarn quality, rubber or spandex behavior, fabric compatibility, and how the elastic will actually be used in the garment.

A dependable manufacturing unit works more like a long-term technical partner than just a seller. Knowing how elastic reacts to washing, repeated stretching, and daily wear helps garment brands reduce the risk of quality issues, rejections, and customer complaints after production.

Buyer Requirements: The First Step Before Sampling

Every successful elastic tape order starts with a clear understanding at the requirement stage. Most quality issues arise not during production, but rather due to unclear discussions at the outset. When expectations are vague, even a satisfactory product can turn into a mismatch later.

Buyers usually share details like elastic width, stretch level, recovery strength, color shade, surface feel, and where the elastic will be used. For example, lingerie elastics need to be soft and gentle on the skin, while denim waistbands require stronger elastic with controlled stretch. Sportswear often needs elastics with high recovery and sweat resistance, and kidswear demands a balance between softness and durability.

At this stage, experienced elastic tape manufacturers ask the right questions instead of making assumptions. They help buyers understand what is technically possible and suggest changes if needed based on actual usage. This discussion helps avoid confusion and sets clear, realistic expectations before the sampling process even begins.

The sampling process is explained simply.

Sampling is the base of trust between buyers and suppliers in the elastic tape industry. It’s not just about producing a small sample piece; it’s about demonstrating the repeatability of the same quality in large-scale production.

Manufacturers experiment with various yarn combinations, rubber or spandex qualities, and machine settings during the sampling stage to achieve the desired outcome. Manufacturers carefully check things like stretch level, recovery, width consistency, and overall look. Often, sampling takes more than one round, which is completely normal when the elastic needs to meet specific or customized requirements.

Professional elastic tape manufacturers treat sampling as an important technical check, not something to rush through. Once a sample is approved, it becomes the reference point for all future bulk orders. Skipping this step or hurrying it often leads to quality mismatches and problems later in production.

Raw Material Selection and Its Impact on Elastic Performance

The long-term performance of an elastic tape depends a lot on the quality of raw materials used. The yarn type affects the elastic’s feel and strength, while the rubber or spandex quality affects its stretch and recovery. Even the dyes used matter, as they affect how well the color stays and whether the elastic keeps its strength over time.

Low-quality materials may look fine at first, but problems start showing after washing or regular use. The elastic can lose its stretch, become hard or brittle, or start fading in color. Skilled elastic tape manufacturers choose raw materials based on where and how the elastic will be used, not just on price. This ensures the elastic performs well throughout the life of the garment.

This understanding of materials doesn’t come overnight. It is built through years of hands-on experience, production trials, and testing across different garment types and usage conditions.

Elastic Tape Production: From Machine Setup to Output

Once the sample is approved, the work moves into bulk production. Making elastic tape in large quantities is a very precise process that needs correct machine settings, proper tension control, and constant monitoring. Even small changes in these settings can lead to problems like uneven width, irregular stretch, or poor recovery.

Modern production facilities use special weaving or knitting machines made specifically for elastic tapes. These machines need to be handled by trained operators who understand how factors like yarn tension, rubber feed, and machine speed affect the final product.

Professional elastic tape manufacturers focus more on keeping the process stable than just producing high volumes. Their main aim is to make sure every roll coming out of the machine matches the approved sample, not just the first few rolls of the batch.

In-Process Quality Checks During Manufacturing

Quality control in elastic tape production doesn’t happen only at the end. It starts right from the moment production begins and continues throughout the process.

During production, teams regularly check important factors like stretch level, recovery, width accuracy, and overall surface finish. Visual checks help spot issues such as uneven weaving or exposed rubber, while performance tests make sure the elastic behaves the same way every time it is stretched.

Established elastic tape manufacturers follow this preventive method because finding problems early saves time, reduces waste, and avoids rework or dispatch delays. More importantly, it helps build long-term trust with buyers, especially when orders are repeated over time.

Color Matching and Shade Consistency in Bulk Orders

Color consistency is one of the trickiest parts of supplying elastic tapes. Even a small difference in shade can become clearly visible once the elastic is stitched into a garment, especially in areas that are exposed or meant to stand out.

To avoid this, tape manufacturers work with approved color references and follow controlled dyeing processes. When buyers place repeat orders, the level of attention becomes even higher so that new production matches the previous batches as closely as possible.

Trusted garment elastic manufacturers keep proper shade records and process details for every order. This helps ensure that buyers receive the same color consistency again and again, building confidence and reliability over long-term business relationships.

Packing Standards and Measurement Accuracy

Once production is finished and approved, the elastic tapes move to the packing stage. The way elastics are packed depends on the buyer’s requirement and how they will be used in production. Some buyers prefer roll packing, while others may need poly wrapping or carton packing for easier handling and storage.

At this stage, measurement accuracy becomes crucial. If roll lengths are incorrect, it can disturb garment production planning and create unnecessary issues later. Reliable tape manufacturers follow clear packing standards and double-check measurements to make sure every roll has the correct length, proper labeling, and is packed safely for transport.

Final Dispatch and Delivery Coordination

The last step in the elastic tape process is dispatch, which is as vital as the previous steps. It requires proper coordination between finished production, completed packing, paperwork, and transport arrangements.

Even when the product quality is perfect, delays during dispatch can disturb garment production schedules. That’s why professional elastic tape manufacturers plan shipments in advance and keep buyers informed about timelines and logistics.

Delivering orders on time builds trust and helps buyers run their factories smoothly without last-minute disruptions or production gaps.

How Reliable Elastic Tape Manufacturers Add Long-Term Value

A good elastic tape partner does much more than just supply material. They support buyers as production grows, help maintain the same quality across different seasons, and reduce day-to-day operational pressure.

By providing technical support, consistent quality, and reliable delivery timelines, professional elastic tape manufacturers work as long-term partners instead of short-term suppliers. This kind of relationship helps both sides by lowering mistakes, improving efficiency, and supporting steady brand growth over time.

How to Choose the Right Elastic Tape Manufacturing Partner

Choosing the right supplier is about much more than just comparing prices. Buyers need to look at how well the supplier handles sampling, where raw materials are sourced from, how production is controlled, how quality is checked, and how clearly they communicate.

Suppliers who are open about their processes, timelines, and even their limitations are usually more reliable. Established elastic tape manufacturers earn trust through consistent performance and clear communication, not by making big or unrealistic promises.

Conclusion

The journey of elastic tape manufacturers from the first sample to the final dispatch goes through many important technical and operational steps. Every stage, whether it is understanding the requirement, developing samples, selecting the right materials, managing production, checking quality, packing, or delivering on time, directly affects how the final garment performs.

When buyers understand this process, they can work more smoothly with their suppliers and make better long-term decisions. Choosing a reliable elastic tape partner means better quality, fewer production issues, and more stable operations.

If you’re looking for a dependable elastic tape partner, Proshiv is here to support your garment business with consistent quality, technical expertise, and reliable supply. Get in touch with Proshiv to discuss your elastic tape requirements and build a partnership you can trust.