Table of Contents

Introduction

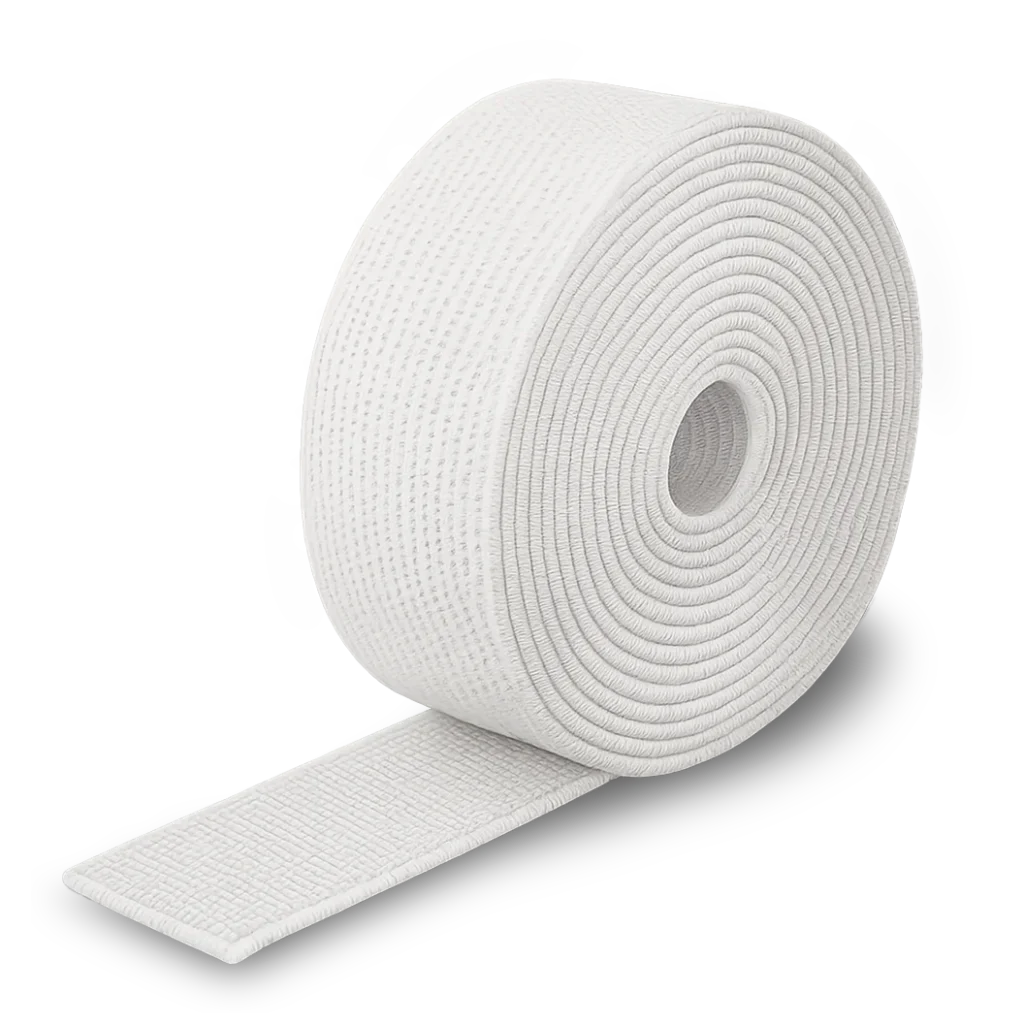

Finding the right supplier for your business can feel overwhelming. Whether you’re making clothing, medical supplies, or sportswear, elastic tape is a crucial component that affects your final product quality. Many buyers rush into partnerships with suppliers without doing proper research, and this often leads to problems down the road.

The truth is, choosing the wrong manufacturer can cost you thousands of dollars in wasted materials, delayed orders, and unhappy customers. But don’t worry – by learning about the most common mistakes, you can avoid these pitfalls and find a reliable partner for your business. In this guide, we’ll walk through seven critical mistakes that buyers make when selecting elastic tape manufacturers. By the end, you’ll know exactly what to look for and what to avoid.

Mistake 1: Focusing Only on Price

When you’re starting a new project or trying to cut costs, it’s tempting to choose the supplier with the lowest price. After all, saving money on materials means better profit margins, right? Not always.

Here’s the problem: the cheapest option often comes with hidden costs that end up being more expensive in the long run. Low-quality elastic tape might break easily, lose its stretch after a few washes, or cause your finished products to fail quality checks. Think about what happens when you use poor-quality elastic tape. Your customers return products. You lose money on replacements. Your brand reputation suffers. Suddenly, those “savings” don’t look so good anymore.

Instead of focusing only on price, look at the overall value. Ask yourself: Will this elastic tape perform well? Will it last? Does the quality match what my customers expect? A slightly higher price upfront can save you significant money and headaches later. The best approach is to compare several suppliers and understand what you’re getting for your money. Look at material quality, durability testing results, and customer feedback alongside the price tag.

Mistake 2: Not Checking Quality Certifications

Certifications might seem like boring paperwork, but they’re actually your safety net. When elastic tape manufacturers have proper certifications, it means their products have been tested by independent organizations. Important certifications to look for include ISO standards, OEKO-TEX certification for materials that touch human skin, and industry-specific safety certifications depending on your needs.

Why does this matter? Let’s say you’re making baby clothing or medical supplies. Using uncertified elastic tape could expose people to toxic substances. This puts your customers at risk and could result in lawsuits or product recalls that destroy your business. A trustworthy manufacturer will happily share their certification documents and explain their quality control processes. If a supplier hesitates or makes excuses about providing this information, consider it a red flag and move on to other options.

Mistake 3: Ignoring Production Capacity and Lead Times

Imagine this scenario: Your business is growing, and you need to double your order quantity. You contact your supplier, only to find out they can’t handle larger orders. Now you’re scrambling to find a new manufacturer while your customers wait. Understanding production capacity from the start prevents this problem.

Ask potential suppliers about their minimum order quantities and maximum production capabilities. Make sure their capacity aligns with both your current needs and future growth plans. Lead times are equally important. If a supplier promises delivery in two weeks but consistently takes six weeks, your entire production schedule falls apart. This leads to missed deadlines, cancelled orders, and frustrated customers.

During your initial conversations, get clear answers about typical production timelines, their busiest seasons, and their track record for on-time delivery. Be cautious of manufacturers who make unrealistic promises. If something sounds too good to be true – like incredibly fast delivery times or unlimited capacity – it probably is.

Mistake 4: Skipping Sample Testing

Never, ever place a large order without testing samples first. This is one of the most expensive mistakes you can make. Samples let you verify that the elastic tape meets your specifications before you commit to buying thousands of meters. You can test the elasticity, check how it holds up after washing, examine the color accuracy, and ensure the width and thickness are correct.

You don’t need fancy equipment to test samples. Stretch the elastic tape multiple times to see if it returns to its original length. Wash it according to your product requirements and check for shrinkage or color fading. Test its strength and examine the texture to ensure it matches your quality standards. If the sample fails any of these tests, you’ve just saved yourself from a costly mistake. If it passes, you can move forward with confidence.

Most reputable suppliers will send samples for free or for a small fee. If a manufacturer refuses to provide samples or makes it difficult to get them, that’s a major warning sign. Walk away and find someone who stands behind their product quality enough to let you test it first.

Mistake 5: Not Researching the Manufacturer's Experience

Experience matters in manufacturing. A company that has been producing elastic tape for many years will understand the nuances of different materials, applications, and quality requirements much better than a brand-new operation. But experience isn’t just about years in business – it’s also about relevant experience in your specific industry.

Check how long potential manufacturers have been in business and ask about their specific expertise. If you need elastic tape for medical applications, a manufacturer who specializes in sportswear elastic might not be the best fit. Request customer references or case studies, and look for online reviews and testimonials. Don’t just take their word for it – contact some of their current or past customers if possible.

Ask these customers about product quality, reliability, and how the manufacturer handles problems when they arise. Also, verify any claims the supplier makes. If they say they work with major international brands, that should be easy to confirm through their website or third-party reviews. Taking time to research properly now saves you from partnership problems later.

Mistake 6: Overlooking Communication and Customer Service

Good communication is the foundation of any successful business relationship. When you’re working with elastic tape manufacturers, especially those in different countries, clear communication becomes even more critical. Pay attention to how suppliers communicate during your initial interactions. Do they respond to emails promptly? Are they patient in answering your questions? Do they provide clear, detailed information?

Language barriers can cause serious problems. Misunderstandings about specifications, delivery dates, or quality requirements can result in wrong products, wasted time, and lost money. Choose manufacturers who have English-speaking staff or good translation support if needed. Customer service reveals how a manufacturer will treat you when problems arise – and problems always arise eventually.

You want a supplier who takes ownership of issues and works with you to find solutions, not one who disappears when things go wrong. Before committing, test their communication by sending detailed questions and evaluating how thoroughly they’re answered. Ask about a hypothetical problem and note their proposed solution. Remember, you’re not just buying a product – you’re building a partnership. Choose manufacturers who treat you with respect and professionalism from day one.

Mistake 7: Failing to Understand Customization Options

Not all elastic tape is created equal. Different applications require different specifications: varying widths, colors, elasticity levels, and materials. Understanding what customization options are available helps ensure you get exactly what you need for your specific products.

Many buyers assume they must choose from standard products, but most elastic tape manufacturers offer customization services. You might be able to get custom widths, specific color matching, different material blends, or special finishes. However, customization usually comes with additional costs and longer lead times. Small custom orders might have higher per-unit prices than standard products.

Ask potential suppliers what customization options they offer, the additional costs involved, and how custom orders affect production time. If you have unique requirements, finding a manufacturer with strong technical expertise becomes even more important. They should be able to guide you on the best materials and specifications for your specific application, helping you make informed decisions that balance quality, cost, and functionality.

How to Choose the Right Elastic Tape Manufacturers

Now that you know what mistakes to avoid, here’s how to move forward with confidence. Start by creating a list of at least three to five potential manufacturers. Check their websites for certifications and experience, read online reviews, and verify their production capabilities match your needs.

During first contact, ask about certifications, inquire about their experience in your specific industry, and request product catalogs. Order samples from your top two or three choices and conduct thorough quality testing. Compare samples side-by-side, considering both quality and price. Before making your final decision, check references from current customers, clarify all terms regarding pricing and lead times, and ensure communication has been smooth and professional.

Consider starting with a smaller trial order to test the relationship. Monitor delivery times and product quality closely. Evaluate how they handle any issues that arise. Assess your overall satisfaction before committing to larger orders. This approach minimizes risk while giving you real-world experience with the manufacturer.

Conclusion

Choosing the right elastic tape manufacturers is one of the most important decisions you’ll make for your business. By avoiding these seven common mistakes, you’ll be well-positioned to find a reliable, high-quality supplier who can support your success and help your business grow.

Remember, don’t rush the process. Take time to research properly, ask questions, test samples, and verify certifications. The effort you invest upfront will pay off through better product quality, fewer headaches, and stronger business growth. The goal isn’t just to find someone who can sell you elastic tape – it’s to build a long-term partnership with a manufacturer who understands your needs and delivers consistent quality every single time.

At Proshiv, we understand that quality and reliability matter to your business. With years of experience in manufacturing premium elastic tapes, we’ve helped countless businesses find the perfect solution for their specific needs. Whether you need standard products or custom specifications, our team is ready to support you with certified quality, transparent communication, and on-time delivery.