Table of Contents

Summary

This blog breaks down elastic tape pricing in a clear and practical way, straight from a manufacturer’s point of view. It is written especially for first-time buyers, sourcing managers, and growing garment brands who want to understand how elastic tape prices are decided in today’s Indian market. It will also help you judge what a fair price looks like and avoid common mistakes that often happen when comparing quotes from different suppliers.

Introduction

This blog breaks down elastic tape pricing in a clear and practical way, straight from a manufacturer’s point of view. It is written especially for first-time buyers, sourcing managers, and growing garment brands who want to understand how elastic tape prices are decided in today’s Indian market. It will also help you judge what a fair price looks like and avoid common mistakes that often happen when comparing quotes from different suppliers.

Understanding Elastic Tape and Why Pricing Varies

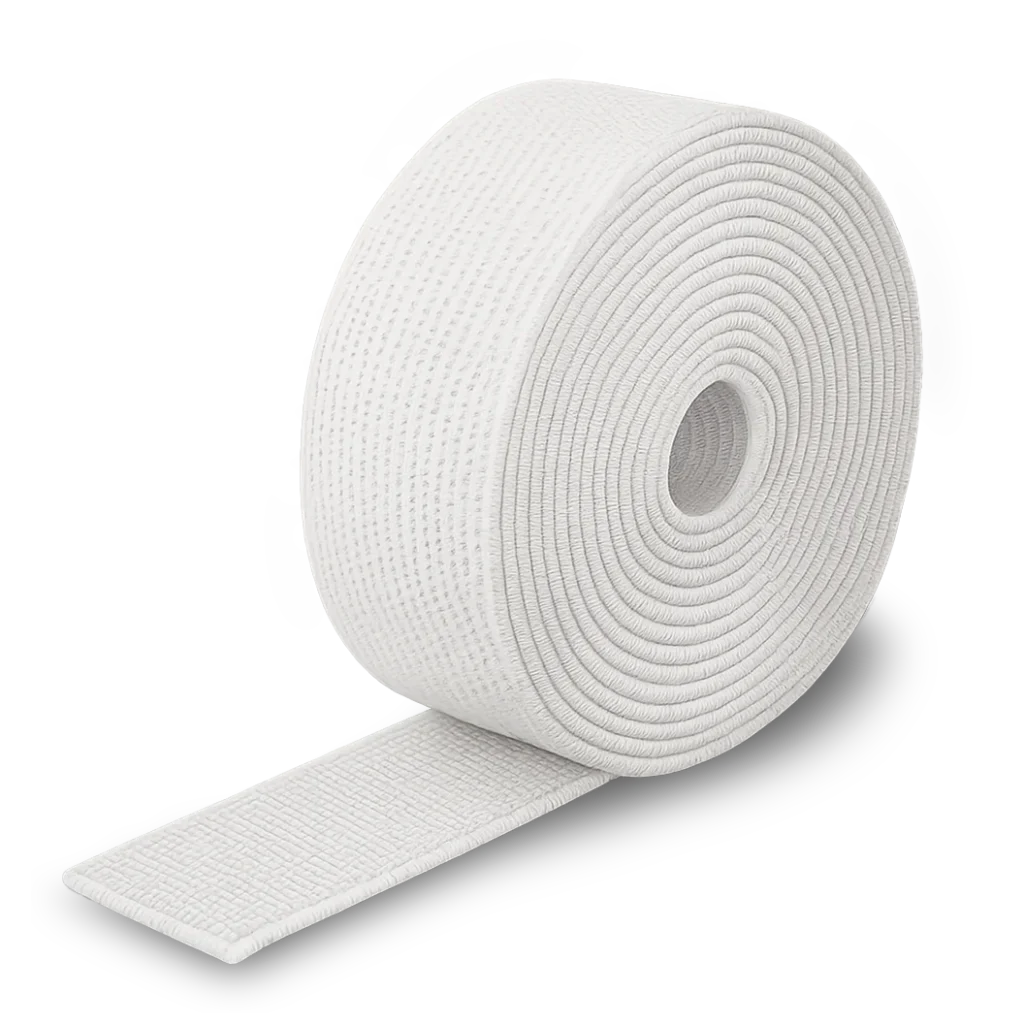

Elastic tape is a narrow, stretchable fabric that helps garments fit better and feel more comfortable. It is commonly used in waistbands, innerwear, sportswear, kidswear, face masks, and even some home furnishing items. At first glance, elastic tape from different suppliers may look almost the same, but the real difference lies inside. The way manufacturers make it, the type of threads they use, and the overall build quality vary a lot, directly impacting the price.

Most elastic tape manufacturers do not follow a fixed market rate. Instead, they calculate prices based on actual production costs. This technique is why two suppliers may quote very different prices for what seems like the same elastic tape. The variation usually comes from factors such as the quality of raw materials, the strength and recovery of elastic threads, the weaving or knitting process, and the level of quality checks done during manufacturing.

Raw Materials Used in Elastic Tape and Their Impact on Price

In elastic tape manufacturing, raw material is the most significant cost factor. Elastic tape is generally made using a mix of polyester, cotton, nylon, and rubber or spandex threads. The quality and ratio of these materials play a major role in how strong the elastic is, how well it stretches and comes back to shape, and how long it lasts after repeated use and washing.

Polyester elastic tapes are commonly used because they give excellent strength and keep pricing relatively stable. Cotton elastic tapes feel softer on the skin, which makes them a popular choice for innerwear and kidswear, but they usually cost more. Nylon and spandex blends provide better stretch and recovery, so the elastic performs well for a longer time, but their use also increases the overall cost.

From a manufacturer’s point of view, using better-quality elastic threads does raise production costs, but it helps avoid common issues like early stretching, breakage, or customer complaints. This is why reliable elastic tape manufacturers usually advise buyers not to go for the cheapest option when the garment needs long-lasting performance and durability.

How Width and Thickness Change Elastic Tape Pricing

Elastic tape width has a direct impact on pricing. Narrow elastic tapes use less raw material and take less time on machines, which is why they are usually priced lower. As the width increases, more yarn is required, machines run under higher loads, and stronger elastic threads are needed, all of which increase the production cost.

Thickness is another important factor. Even if two elastic tapes have the same width, their prices can be different because one may use more elastic thread or have a tighter, denser weave. Thicker elastic tapes generally offer better grip, stronger stretch, and a longer usable life, but they also cost more to manufacture.

Because of these variations, experienced elastic tape manufacturers always ask buyers to clearly confirm the required width, thickness, and stretch level before giving a final price. This helps ensure accurate pricing and avoids confusion later.

Manufacturing Process and Quality Standards

Elastic tapes are made using different manufacturing methods such as woven, knitted, and crochet techniques. Each method has its own production process and cost. Woven elastic tapes are usually stronger and more stable, which makes them suitable for garments that need firm support. Knitted elastic tapes, on the other hand, are softer and more flexible, so they are often used where comfort is more important.

Manufacturers who regularly carry out quality checks like colorfastness testing, stretch recovery testing, and batch-wise inspection usually have slightly higher prices. However, these checks help maintain consistent quality and reduce the chances of defects or returns.

Experienced elastic tape manufacturers set their prices by focusing on long-term performance rather than just the initial cost. This approach helps buyers avoid quality issues and ensures the elastic performs well throughout the life of the garment.

Current Elastic Tape Prices in the Indian Market

Below is a practical price overview based on current quotations shared by Indian elastic tape manufacturers. These prices give a fair idea of what is being offered in the market right now. Actual rates may go up or down depending on factors like order quantity, width, quality level, and specific requirements shared by the buyer.

| Elastic Tape Type | Common Usage | Approximate Price (₹ per meter) |

|---|---|---|

| Basic narrow elastic (4–10 mm) | Masks, light garments | ₹0.75 – ₹10 |

| Standard garment elastic | Waistbands, casual wear | ₹1 – ₹8 |

| Mid-range elastic tape | Regular apparel production | ₹2 – ₹16 |

| Premium elastic tape | Sportswear, innerwear | ₹4 – ₹23 |

| Heavy-duty / special elastic | Industrial or custom use | ₹3 – ₹25+ |

These prices represent the usual rates that well-established elastic tape manufacturers quote for bulk orders. If the order quantity is small or the elastic tape requires custom colors, designs, or special specifications, the cost is generally higher.

How Elastic Tape Manufacturers Quote Prices

Most manufacturers prefer to quote elastic tape prices on a per-meter basis because it makes cost calculation simple for buyers. Garment manufacturers can easily match the price with their per-piece consumption. In some cases, especially for smaller garment units or retail buyers, elastic tape is also offered in rolls with a fixed length.

Bulk buyers usually receive better pricing since larger volumes help manufacturers run machines efficiently and reduce overall production cost. On the other hand, custom requirements like special colors, printed logos, or non-standard widths often increase the price because they involve extra setup time and material wastage.

Elastic tape manufacturers are transparent about how they calculate prices. They explain the cost factors clearly instead of giving unclear or inconsistent quotations, which helps buyers make confident sourcing decisions.

Why the Cheapest Elastic Tape Is Not Always the Best Choice

Many buyers compare suppliers only on the per-meter price, thinking that lower cost means better savings. This approach often creates problems later, such as the elastic losing stretch after washing, uneven elasticity, or even breaking during stitching and use.

Manufacturers with real production experience understand that low-quality elastic tape leads to higher garment rejections, customer complaints, and damage to the brand’s image. In most cases, paying a little more for dependable elastic tape actually reduces losses and saves money over time.

That is why experienced elastic tape manufacturers usually guide buyers toward the right quality level based on how the elastic will be used in the garment, rather than simply offering the cheapest option.

Tips for Buyers When Comparing Elastic Tape Prices

Before choosing a supplier, buyers should always check samples instead of deciding only on price. Things like stretch recovery, softness, color stability, and how the elastic behaves during stitching make a big difference in actual garment performance.

It is also important to clearly discuss details such as minimum order quantity, delivery timelines, and replacement or rejection policies. Reliable manufacturers are open about these points and focus on building long-term business relationships rather than just closing a single order.

Selecting the right elastic tape manufacturers is not about finding the lowest price. It is about getting consistent quality, dependable supply, and fair pricing that supports smooth production in the long run.

The Role of Manufacturer Experience in Pricing

Manufacturers who have been in the industry for many years understand how the market changes, how raw material prices move, and what the garment industry actually needs. Because of this experience, their pricing is usually stable and well thought out, not based on short-term market fluctuations.

These manufacturers invest in better machines, trained workers, and strong quality control systems. This builds credibility and trust, which are key parts of EEAT. Their focus is on delivering consistent performance rather than cutting corners.

When buyers work with experienced elastic tape manufacturers, they gain more than just a supplier. They get practical technical advice, a reliable supply chain, and pricing that remains predictable over time.

Conclusion

Elastic tape pricing is decided by real, practical factors, not guesswork. Things like material quality, width, thickness, manufacturing process, and order quantity all affect the final price. When buyers understand these basics, they can take better sourcing decisions and avoid mistakes that later turn into losses.

For garment brands and manufacturers, working with reliable elastic tape manufacturers means getting consistent quality, fair pricing, and a stable supply over the long term. Instead of running behind the lowest rate, focusing on performance and reliability always gives better results.

If you are looking for dependable quality and transparent pricing, Proshiv works closely with garment manufacturers to supply elastic tapes that perform well in real production conditions.